Galvanized I-Steel

Category:

Universal Beam (l-Beam)

Galvanized I-Steel

Galvanized I-Steel Description

Hot-dip galvanized I-steel is also called hot-dip galvanized I-steel or hot-dip galvanized I-steel. It is to immerse the I-beam after derusting into molten zinc at about 500 ℃ to attach a zinc layer to the surface of the I-beam, thus achieving the purpose of anti-corrosion. It is suitable for strong corrosive environments such as various strong acids and alkali fogs.

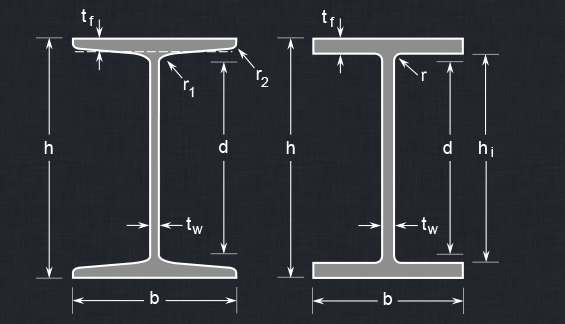

Product Parameters

| Material | A36, St37, S235J0, S235J2, St52, S355JR, Q195, Q215, Q235B, Q345B, S235JR, S355JR, S355, SS440, SM400A, SM400B, A572 GR50/GR60, SS540 |

| Scope of Production | H100*100-H400*400, H150*75 -H900*300 |

| Length | 6m, 9m, 12m or acording to customer requirements |

| Technology | Hot Rolled, Welded |

| Standard | ASTM, AISI, JIS, GB, DIN, EN |

| Surface | Galvanized, Painted or according to your requirements |

| Supply Capacity | 2000 tons/Day |

| Business Type | Manufacturer |

| Certificate | ISO, SGS, BV |

| Application | Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc. |

| Loading Port | Any port in China |

| Packaging | Standard export packing or as your request |

| Payment Method | Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal. |

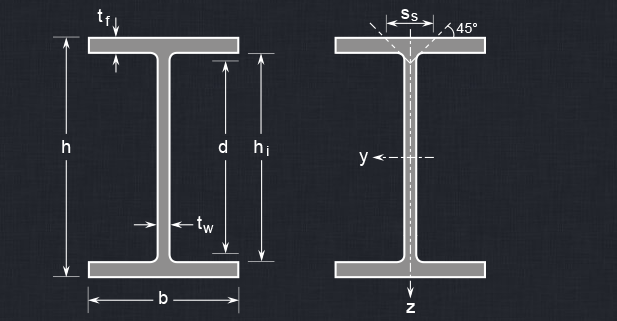

Standard I Beam Sizes

American Sizes

|

Description |

lbs/ft |

h in. |

b in. |

tw in. |

tf in. |

|

S 3x5.70 |

5.7 |

3 |

2.33 |

0.17 |

0.26 |

|

S 3x7.50 |

7.5 |

3 |

2.509 |

0.349 |

0.26 |

|

S 4x7.70 |

7.7 |

4 |

2.663 |

0.193 |

0.293 |

|

S 4x9.50 |

9.5 |

4 |

2.796 |

0.326 |

0.293 |

|

S 5x10.0 |

10 |

5 |

3.004 |

0.214 |

0.326 |

|

S 5x14.75 |

14.75 |

5 |

3.284 |

0.494 |

0.326 |

|

S 6x12.5 |

12.5 |

6 |

3.332 |

0.232 |

0.359 |

|

S 6x17.25 |

17.25 |

6 |

3.565 |

0.465 |

0.359 |

|

S 7x15.3 |

15.3 |

7 |

3.662 |

0.252 |

0.392 |

|

S 7x20.0 |

20 |

7 |

3.86 |

0.45 |

0.392 |

|

S 8x18.4 |

18.4 |

8 |

4.001 |

0.271 |

0.425 |

|

S 8x23.0 |

23 |

8 |

4.171 |

0.441 |

0.425 |

|

S 10x25.4 |

25.4 |

10 |

4.661 |

0.311 |

0.491 |

|

S 10x35.0 |

35 |

10 |

4.944 |

0.594 |

0.491 |

|

S 12x31.8 |

31.8 |

12 |

5 |

0.35 |

0.544 |

|

S 12x35.0 |

35 |

12 |

5.078 |

0.428 |

0.544 |

|

S 12x40.8 |

40.8 |

12 |

5.252 |

0.472 |

0.659 |

|

S 12x50.0 |

50 |

12 |

5.477 |

0.687 |

0.659 |

|

S 15x42.9 |

42.9 |

15 |

5.501 |

0.411 |

0.622 |

|

S 15x50.0 |

50 |

15 |

5.64 |

0.55 |

0.622 |

European Sizes

|

Description |

G kg/m |

h |

b |

tw |

tf |

|

IPE AAAA 80 |

3.9 |

76 |

46 |

2.9 |

3.1 |

|

IPE AAA 80 |

4.7 |

78 |

46 |

3 |

4 |

|

IPE AA 80 |

4.9 |

78 |

46 |

3.2 |

4.2 |

|

IPE A 80 |

5 |

78 |

46 |

3.3 |

4.2 |

|

IPE 80 |

6 |

80 |

46 |

3.8 |

5.2 |

|

IPE AAAA 100 |

5.3 |

96 |

55 |

2.9 |

3.6 |

|

IPE AAA 100 |

6.5 |

97 |

55 |

3.6 |

4.5 |

|

IPE AA 100 |

6.5 |

97.6 |

55 |

3.6 |

4.5 |

|

IPE A 100 |

6.7 |

98 |

55 |

3.6 |

4.7 |

|

IPE 100 |

7.9 |

100 |

55 |

4.1 |

5.7 |

|

IPE AAAA 120 |

6.6 |

115 |

64 |

3 |

3.9 |

|

IPE AAA 120 |

7.8 |

117 |

64 |

3.5 |

4.6 |

|

IPE AA 120 |

8.2 |

117 |

64 |

3.8 |

4.8 |

|

IPE A 120 |

8.5 |

117.6 |

64 |

3.8 |

5.1 |

|

IPE 120 |

10.3 |

120 |

64 |

4.4 |

6.3 |

|

IPE AAAA 140 |

8.1 |

134 |

73 |

3.3 |

4.1 |

|

IPE AAA 140 |

9.4 |

136 |

73 |

3.5 |

5 |

|

IPE AA 140 |

9.9 |

136.6 |

73 |

3.8 |

5.2 |

|

IPE A 140 |

10.4 |

137.4 |

73 |

3.8 |

5.6 |

|

IPE 140 |

12.8 |

140 |

73 |

4.7 |

6.9 |

|

IPE AAAA 160 |

9.9 |

154 |

82 |

3.6 |

4.3 |

|

IPE AAA 160 |

11.4 |

156 |

82 |

3.7 |

5.4 |

|

IPE AA 160 |

12 |

156.4 |

82 |

4 |

5.6 |

|

IPE A 160 |

12.4 |

157 |

82 |

4 |

5.9 |

|

IPE 160 |

15.5 |

160 |

82 |

5 |

7.4 |

|

IPE AAAA 180 |

12.3 |

174 |

91 |

3.9 |

4.9 |

|

IPE AAA 180 |

13.9 |

176 |

91 |

3.9 |

6 |

|

IPE AA 180 |

14.7 |

176.4 |

91 |

4.3 |

6.2 |

|

IPE A 180 |

15.1 |

177 |

91 |

4.3 |

6.5 |

|

IPE 180 |

18.6 |

180 |

91 |

5.3 |

8 |

|

IPE O 180 |

21.1 |

182 |

92 |

6 |

9 |

|

IPE AAAA 200 |

14.3 |

193 |

100 |

4.1 |

5.2 |

|

IPE AAA 200 |

16.4 |

196 |

100 |

4.1 |

6.5 |

|

IPE AA 200 |

17.3 |

196.4 |

100 |

4.5 |

6.7 |

|

IPE A 200 |

17.8 |

197 |

100 |

4.5 |

7 |

|

IPE 200 |

21.8 |

200 |

100 |

5.6 |

8.5 |

|

IPE O 200 |

24.6 |

202 |

102 |

6.2 |

9.5 |

|

IPE AA 220 |

20.6 |

216.4 |

110 |

4.7 |

7.4 |

|

IPE A 220 |

21.6 |

217 |

110 |

5 |

7.7 |

|

IPE 220 |

25.7 |

220 |

110 |

5.9 |

9.2 |

|

IPE O 220 |

29 |

222 |

112 |

6.6 |

10.2 |

|

IPE AA 240 |

23.9 |

236.4 |

120 |

4.8 |

8 |

|

IPE A 240 |

25.1 |

237 |

120 |

5.2 |

8.3 |

|

IPE 240 |

29.8 |

240 |

120 |

6.2 |

9.8 |

|

IPE O 240 |

33.5 |

242 |

122 |

7 |

10.8 |

|

IPE A 270 |

29.8 |

267 |

135 |

5.5 |

8.7 |

|

IPE 270 |

35.2 |

270 |

135 |

6.6 |

10.2 |

|

IPE O 270 |

41.6 |

274 |

136 |

7.5 |

12.2 |

|

IPE A 300 |

35.7 |

297 |

150 |

6.1 |

9.2 |

|

IPE 300 |

41.5 |

300 |

150 |

7.1 |

10.7 |

|

IPE O 300 |

48.7 |

304 |

152 |

8 |

12.7 |

|

IPE A 330 |

41.6 |

327 |

160 |

6.5 |

10 |

|

IPE 330 |

47.9 |

330 |

160 |

7.5 |

11.5 |

|

IPE O 330 |

55.9 |

334 |

162 |

8.5 |

13.5 |

|

IPE A 360 |

49 |

357.6 |

170 |

6.6 |

11.5 |

|

IPE 360 |

56 |

360 |

170 |

8 |

12.7 |

|

IPE O 360 |

65.1 |

364 |

172 |

9.2 |

14.7 |

|

IPE A 400 |

55.5 |

397 |

180 |

7 |

12 |

|

IPE 400 |

64.6 |

400 |

180 |

8.6 |

13.5 |

|

IPE O 400 |

74.1 |

404 |

182 |

9.7 |

15.5 |

|

IPE V 400 |

82.6 |

408 |

182 |

10.6 |

17.5 |

|

IPE A 450 |

65.4 |

447 |

190 |

7.6 |

13.1 |

|

IPE 450 |

76.1 |

450 |

190 |

9.4 |

14.6 |

|

IPE O 450 |

91.1 |

456 |

192 |

11 |

17.6 |

|

IPE V 450 |

102.6 |

460 |

194 |

12.4 |

19.6 |

|

IPE A 500 |

77.9 |

497 |

200 |

8.4 |

14.5 |

|

IPE 500 |

89.4 |

500 |

200 |

10.2 |

16 |

|

IPE O 500 |

106.4 |

506 |

202 |

12 |

19 |

|

IPE V 500 |

128.3 |

514 |

204 |

14.2 |

23.0 |

|

IPE A 550 |

89.9 |

547 |

210 |

9 |

15.7 |

|

IPE 550 |

103.6 |

550 |

210 |

11.1 |

17.2 |

|

IPE O 550 |

120.9 |

556 |

212 |

12.7 |

20.2 |

|

IPE V 550 |

157.7 |

566 |

216 |

17.1 |

25.2 |

|

IPE A 600 |

105.7 |

597 |

220 |

9.8 |

17.5 |

|

IPE 600 |

120.9 |

600 |

220 |

12 |

19 |

|

IPE O 600 |

153.5 |

610 |

224 |

15 |

24 |

|

IPE V 600 |

183.1 |

618 |

228 |

18 |

28 |

|

IPE 750 x 134 |

134.5 |

750 |

264 |

12.0 |

15.5 |

|

IPE 750 x 147 |

148.0 |

753 |

265 |

13.2 |

17.0 |

|

IPE 750 x 173 |

175.1 |

762 |

267 |

14.4 |

21.6 |

|

IPE 750 x 196 |

198.7 |

770 |

268 |

15.6 |

25.4 |

FACTORY

We are a steel manufacturer with a long history and reputation for excellence. Since our establishment in 2018, we have always been committed to providing customers with the highest quality and most efficient steel products and steel deep processing services to meet their needs in various engineering projects.

CUSTOMER VISITS

In the future development, we will continue to uphold the concepts of professionalism, integrity, innovation and unity, continuously improve product quality and service levels, and provide customers with more high-quality and efficient steel products and services. We look forward to working with you to create a better future!

APPLICATION

Our product range covers various specifications of steel plates, steel sections, steel pipes, etc., which are widely used in construction, bridges, machinery, ships, oil, natural gas, and other fields. We always adhere to strict quality management to ensure that every product meets national standards and customer requirements.

HONOR

RELATED PRODUCTS