Hastelloy C-22 Bar

Category:

Alloy Bar

Hastelloy C-22 Bar

Hastelloy C-22 Bar Description

The main elements of Hastelloy C22 bar include cobalt, chromium, tungsten, molybdenum and small amounts of aluminum, titanium and nitrogen. Among them, cobalt element can improve the strength and hardness of the alloy, chromium element has an important impact on the corrosion resistance of the alloy, tungsten and molybdenum can improve the high-temperature strength of the alloy. In addition, aluminum and titanium elements can help refine the grains and improve the toughness of the alloy, while the addition of nitrogen can improve the strength and corrosion resistance of the alloy. What is more, it has good plasticity and toughness and can be used for cold and hot processing. Hastelloy C22 bar also exhibits excellent oxidation resistance and creep resistance at high temperatures, making it a popular choice in aerospace, chemical industry, petroleum fields.

Product Parameters

Product Name | Hastelloy C-22 Bar | |

Outer Diameter | Round Bar | 4mm-500mm |

Hexagon Bar | 18mm-57mm (11/16″ to 2-3/4″) | |

Square Bar | 18mm-47mm (11/16″ to 1-3/4″) | |

Flat Steel | 1/2 "to 10", Thickness: 2mm-150mm, Can provide customized | |

Length | 1-6 meters, Length can be customized | |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. | |

Surface | Black, Bright Polished, Rough Turning, Matt Surface Treatment, NO.4, BA, etc. | |

Certificate | ISO, SGS, BV | |

Production Technology | Hot Rolling, Cold Rolling | |

Chemical Composition

C | Si | P | S | V | Cr | Mn | Fe | Co | Ni | Mo | W |

0.015 max | 0.08 max | 0.02 max | 0.02 max | 0.35 max | 20.0 - 22.5 | 0.50 max | 2.0-6.0 | 2.5 max | Remainder | 12.5 - 14.5 | 2.5 - 3.5 |

Mechanical Properties

Tensile Strength (ksi) | 0.2% Yield Strength (ksi) | Elongation% in 2 inches |

100 | 45 | 45 |

Physical Performance

| Units | Temperature in°C |

Density | 8.69 g/cm³ | 24°C |

Specific Heat | 0.093 Kcal/kg.C | 52° |

Melting Range | 1357-1399°C | - |

Modulus of Elasticity | 205.5 KN/mm² | - |

Electrical Resistivity | 113.7 µΩ.cm | 24 ° |

Coefficient of Expansion | 12.4 µm/m °C | 24-93° |

Thermal Conductivity | 10.1 w/m-° K | 48° |

Scope of Application

C- 276 alloy is used in pesticide production, phosphoric acid production, pickling system, plate heat exchanger, selective leaching system, SO2 cooling tower, sulfonation system, shell and tube heat exchanger, surfacing welding valve, etc.

|

|

|

EN |

UNS |

| Hastelloy | |||

| Alloy C-276 |

Hastelloy C-276 |

2.4819 |

N10276 |

| Alloy C-22 |

Hastelloy C-22 |

2.4602 |

N06022 |

| Alloy B2 |

Hastelloy B2 |

2.4617 |

N10665 |

| Alloy B3 |

Hastelloy B3 |

2.4600 |

N01675 |

| Alloy X |

Hastelloy X |

2.4655 |

N06002 |

| Monel | |||

| Alloy 400 |

Monel 400 |

2.4360 |

N04400 |

| Alloy R-405 |

Monel R-405 |

- |

N04405 |

| Alloy K-500 |

Monel K-500 |

2.4375 |

N05500 |

| Inconel | |||

| Alloy 600 |

Inconel 600 |

2.4816 |

N06600 |

| Alloy 601 |

Inconel 601 |

2.4851 |

N06601 |

| Alloy 625 |

Inconel 625 |

2.4856 |

N06625 |

| Alloy 718 |

Inconel 718 |

1.4668 |

N07718 |

| Incoloy | |||

| Alloy 800 |

Incoloy 800 |

1.4876 |

N08800 |

| Alloy 800H / 800HT |

Incoloy 800H / 800HT |

1.4958 / 1.4959 |

N08810 / N08811 |

| Alloy 825 |

Incoloy 825 |

2.4858 |

N08825 |

| Alloy 925 |

Incoloy 925 |

- |

N09925 |

| Alloy DS |

Incoloy DS |

- |

- |

| Nickel | |||

| Alloy 200 |

Nickel 200 |

2.4066 |

N02200 |

| Alloy 201 |

Nickel 201 |

2.4068 |

N02201 |

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

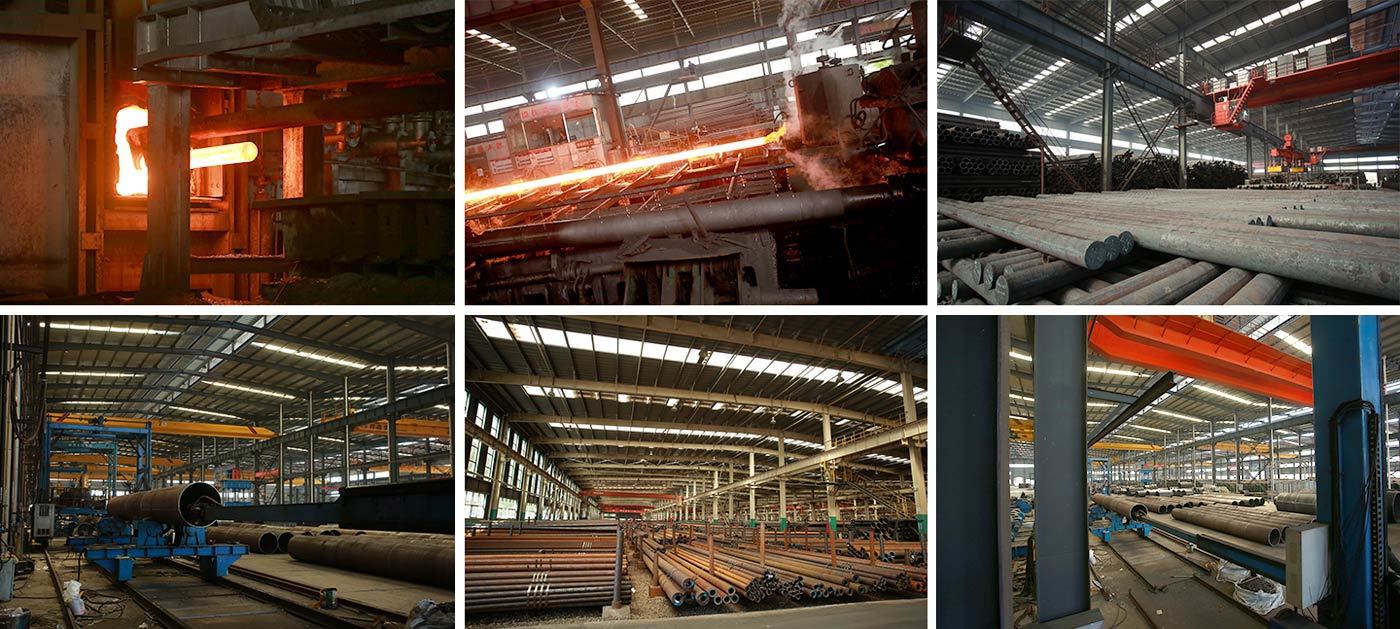

FACTORY

We are a steel manufacturer with a long history and reputation for excellence. Since our establishment in 2018, we have always been committed to providing customers with the highest quality and most efficient steel products and steel deep processing services to meet their needs in various engineering projects.

CUSTOMER VISITS

In the future development, we will continue to uphold the concepts of professionalism, integrity, innovation and unity, continuously improve product quality and service levels, and provide customers with more high-quality and efficient steel products and services. We look forward to working with you to create a better future!

APPLICATION

Our product range covers various specifications of steel plates, steel sections, steel pipes, etc., which are widely used in construction, bridges, machinery, ships, oil, natural gas, and other fields. We always adhere to strict quality management to ensure that every product meets national standards and customer requirements.

HONOR

RELATED PRODUCTS