5005 Aluminum Bar

Category:

Aluminum Bar

5005 Aluminum Bar

5005 Aluminum Bar Description

5005 aluminum bar is made from a common aluminum alloy material composed of aluminum and other alloy elements. Its chemical composition mainly consists of aluminum, making up more than 99.7%, as well as small amounts of magnesium, silicon, and iron. 5005 aluminum alloy are highly resistant to oxidation, corrosion, fading and other problems, having remarkable oxidation resistance in atmospheric environment. Besides, 5005 aluminum bar has good plasticity and processability, as it can be formed through various methods such as cold working and hot working. The process of 5005 aluminum bar has good adjustability. Its hardness, strength, plasticity and other properties can be flexibly adjusted through appropriate heat treatment processes.

Product Parameters

|

Diameter |

5-650mm or customized |

Length |

100-2000mm or customized |

|

Certificate |

ISO, SGS, BV |

||

|

Standard |

JIS, AISI, ASTM, GB, DIN, EN, etc. |

||

|

Brand |

1000 Series: 1050, 1060, 1070, 1100, 1200, 1235, etc. 3000 Series: 3003, 3004, 3005, 3104, 3105, 3A21, etc. 5000 Series: 5005, 5052, 5083, 5086, 5154, 5182, 5251, 5754, 5A05, etc. 6000 Series: 6061, 6063, 6082, 6A02, etc. 7000 Series: 7050, 7475, 7075, etc. 8000 Series: 8A06, 8011, 8090, etc. |

||

|

Surface |

Coating, Embossing, Drawing, Polishing, Anodizing, etc. |

||

|

OEM Service |

Punching, Cutting special size, Making flat surface, Surface treatment, etc. |

||

|

Delivery Time |

Received 30% after deposit 7-15 working days |

||

|

Application |

Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields |

||

|

Sample |

Free Offers Sample |

||

|

Packaging |

Strapping, Plastic bag, Film, Wooden pallet Standard seaworthy export packing or according to customer requirement |

||

Chemical Composition

|

Alloy |

Si |

Fe |

Cu |

Mn |

Mg |

Cr |

Zn |

Ti |

Others: Each |

Others: Total |

Al: Min. |

|

1050 |

0.25 |

0.40 |

0.05 |

0.05 |

0.05 |

- |

0.05 |

0.03 |

0.03 |

- |

99.50 |

|

1060 |

0.25 |

0.35 |

0.05 |

0.03 |

0.03 |

- |

0.05 |

0.03 |

0.03 |

- |

99.60 |

|

1070 |

0.20 |

0.25 |

0.04 |

0.03 |

0.03 |

- |

0.04 |

0.03 |

0.05 |

- |

99.70 |

|

1100 |

0.95 Si Fee |

0.05~0.20 |

0.05 |

- |

- |

0.1 |

- |

0.05 |

0.15 |

99.0 |

|

|

2014 |

0.5~1.2 |

0.7 |

3.9~5.0 |

0.4~1.2 |

0.2~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

2017 |

0.2~0.8 |

0.7 |

3.5~4.5 |

0.4~1.0 |

0.4~0.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

91.5 - 95.5 |

|

2024 |

0.50 |

0.50 |

3.8~4.9 |

0.3~0.9 |

1.2~1.8 |

0.10 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

3003 |

0.60 |

0.70 |

0.05~0.20 |

1.0~1.5 |

- |

- |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

3A21 |

0.60 |

0.70 |

0.20 |

1.0-1.6 |

0.05 |

- |

0.15 |

0.1-0.2 |

- |

- |

Allowance |

|

3004 |

0.30 |

0.70 |

0.25 |

1.0~1.5 |

0.8~1.3 |

- |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

3005 |

0.60 |

0.70 |

0.30 |

1.0~1.5 |

0.2~0.6 |

0.10 |

0.25 |

0.10 |

0.05 |

0.15 |

Allowance |

|

3105 |

0.60 |

0.70 |

0.30 |

0.3~0.8 |

0.2~0.8 |

0.20 |

0.40 |

0.10 |

0.05 |

0.15 |

Allowance |

|

5005 |

0.30 |

0.70 |

0.20 |

0.20 |

0.5~1.1 |

0.1 |

0.25 |

- |

0.05 |

0.15 |

Allowance |

|

5052 |

0.25 |

0.40 |

0.10 |

0.10 |

2.2~2.8 |

0.15~0.35 |

0.10 |

- |

0.05 |

0.15 |

Allowance |

|

5754 |

0.40 |

0.40 |

0.10 |

0.50 |

2.6~3.6 |

0.30 |

0.20 |

0.15 |

0.05 |

0.15 |

Allowance |

|

5A05 |

0.50 |

0.50 |

0.10 |

0.3-0.6 |

4.8-5.5 |

- |

0.20 |

- |

0.05 |

0.05 |

Allowance |

|

5083 |

0.40 |

0.40 |

0.10 |

0.4~1.0 |

4.0~4.9 |

0.05~0.25 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6061 |

0.40~0.8 |

0.70 |

0.15~0.4 |

0.15 |

0.8~1.2 |

0.04~0.35 |

0.25 |

0.15 |

0.05 |

0.15 |

Allowance |

|

6082 |

0.70~1.3 |

0.50 |

0.10 |

0.4~1.0 |

0.6~1.2 |

0.25 |

0.20 |

0.10 |

0.05 |

0.15 |

Allowance |

|

7075 |

0.40 |

0.50 |

1.2~2.0 |

0.30 |

2.1~2.9 |

0.18~0.28 |

5.1~6.1 |

0.20 |

0.05 |

0.15 |

Allowance |

Mechanical Properties

|

Tensile Strength (MPa) |

Test Stress (MPa) |

Hardness HV |

Elongation Rate (%) |

|

160 |

145 |

46 |

11 |

Physical Performance

|

Density |

Melting Point |

Modulus of Elasticity |

Thermal Conductivity |

Resistance Rate |

|

2.7 Kg/m³ |

655 °C |

69.5 GPa |

201 W/m.K |

0.033x10 ^-6 Ω.m |

Annealing State

|

Brand |

Annealing State |

|

1xxx: 1050, 1050A, 1060, 1100 |

O, H12, H14, H16, H18, H22, H24, H26, H28, H111 |

|

3xxx: 3003, 3004, 3005, 3105 |

|

|

5xxx: 5005, 5052, 5754, 5083, 5086, 5182, 5049, 5251, 5454 |

O, H22, H24, H26, H28, H32, H34, H36, H38, H111 |

|

6xxx: 6061, 6082 |

T4, T6, T451, T651 |

|

2xxx: 2024 |

T3, T351, T4 |

|

7xxx: 7075 |

T6, T651 |

Scope of Application

|

Aluminum Uses And Application Area |

|

|

Food Packaging |

Beverage can ends, cans, bottle caps, etc. |

|

Building |

Curtain walls, cladding, suspended ceilings, thermal insulation, venetian blinds, etc. |

|

Transportation |

Auto parts, passenger car bodies, aviation ships and air cargo containers. |

|

Electronic Equipment |

Electrical appliances, communication equipment,PCPlate drilling guide, lighting and heat dissipation materials, etc. |

|

Consumer Goods |

Umbrellas, cooking utensils, sports equipment, etc |

|

Other |

Military, color coated aluminum plate |

|

Alloy Series |

GB |

ASTM |

EN |

|

1xxx Series |

1050 |

- |

- |

|

1050A |

- |

EN AW-1050A |

|

|

1060 |

1060 |

- |

|

|

1100 |

1100 |

- |

|

|

2xxx Series |

2024 |

2024 |

EN AW-2024 |

|

3xxx Series |

3003 |

3003 |

EN AW-3003 |

|

3004 |

3004 |

EN AW-3004 |

|

|

3005 |

3005 |

EN AW-3005 |

|

|

3105 |

3105 |

EN AW-3105 |

|

|

5xxx Series |

5005 |

5005 |

EN AW-5005 |

|

5052 |

5052 |

EN AW-5052 |

|

|

5754 |

5754 |

EN AW-5754 |

|

|

5083 |

5083 |

EN AW-5083 |

|

|

5086 |

5086 |

EN AW-5086 |

|

|

5182 |

- |

EN AW-5182 |

|

|

5049 |

- |

EN AW-5049 |

|

|

5251 |

- |

EN AW-5251 |

|

|

6xxx Series |

6061 |

6061 |

EN AW-6061 |

|

6082 |

- |

EN AW-6082 |

|

|

7xxx Series |

7075 |

7075 |

EN AW-7075 |

PACKING AND SHIPPING

We have our own transportation fleet with the most convenient transportation and timely delivery.The company's products are exported to more than 70 countries and regions in the world, including Europe, America, Germany, South Korea, Indonesia, Bangladesh, etc.

FACTORY

We are a steel manufacturer with a long history and reputation for excellence. Since our establishment in 2018, we have always been committed to providing customers with the highest quality and most efficient steel products and steel deep processing services to meet their needs in various engineering projects.

CUSTOMER VISITS

In the future development, we will continue to uphold the concepts of professionalism, integrity, innovation and unity, continuously improve product quality and service levels, and provide customers with more high-quality and efficient steel products and services. We look forward to working with you to create a better future!

APPLICATION

Our product range covers various specifications of steel plates, steel sections, steel pipes, etc., which are widely used in construction, bridges, machinery, ships, oil, natural gas, and other fields. We always adhere to strict quality management to ensure that every product meets national standards and customer requirements.

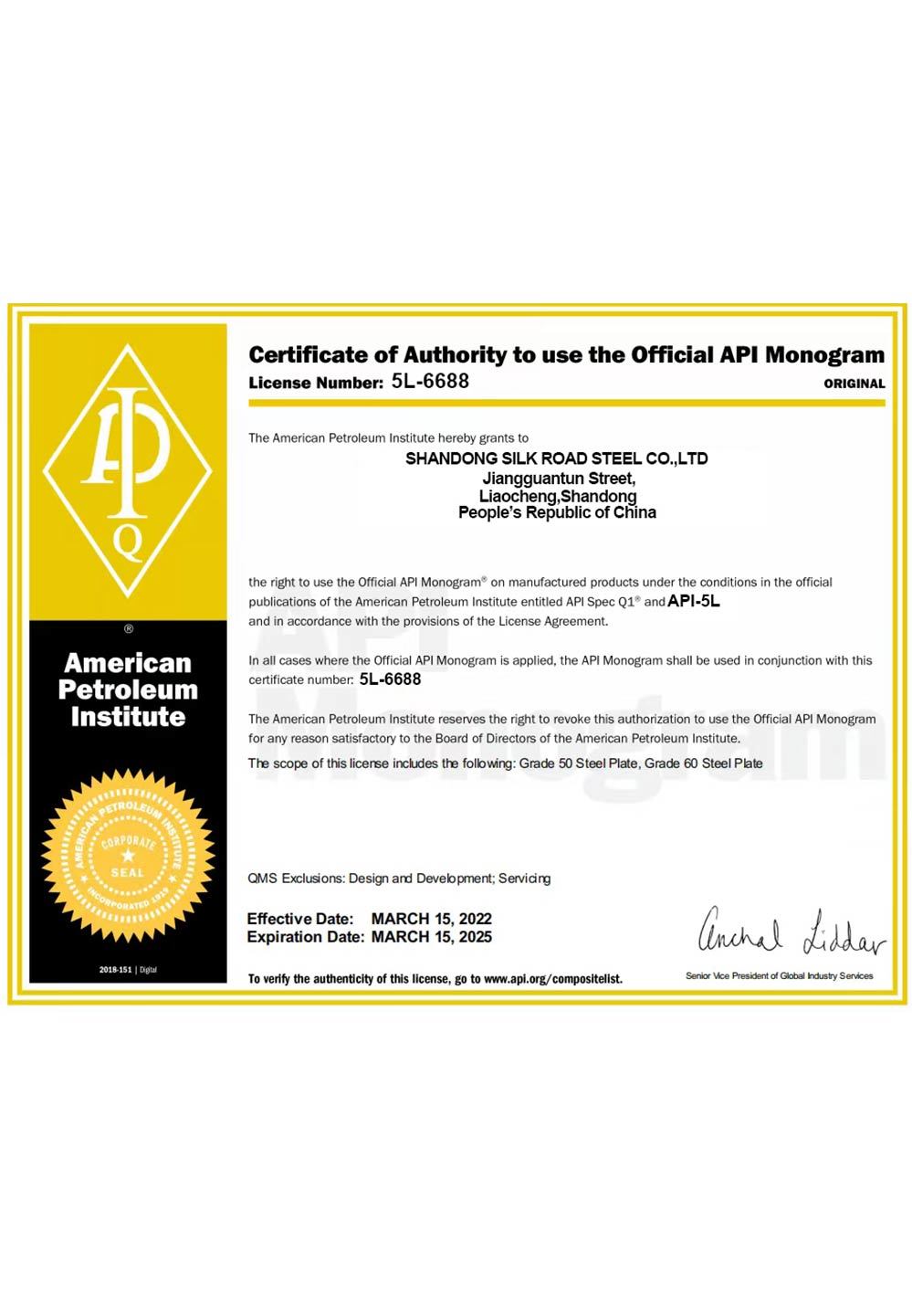

HONOR

RELATED PRODUCTS